Our

Pledge

One Tree Planted

With every NE1D Educational Lab Bath sold, we donate some of our profits to One Tree Planted, we aim to plant 1000 trees a year!

Our Products

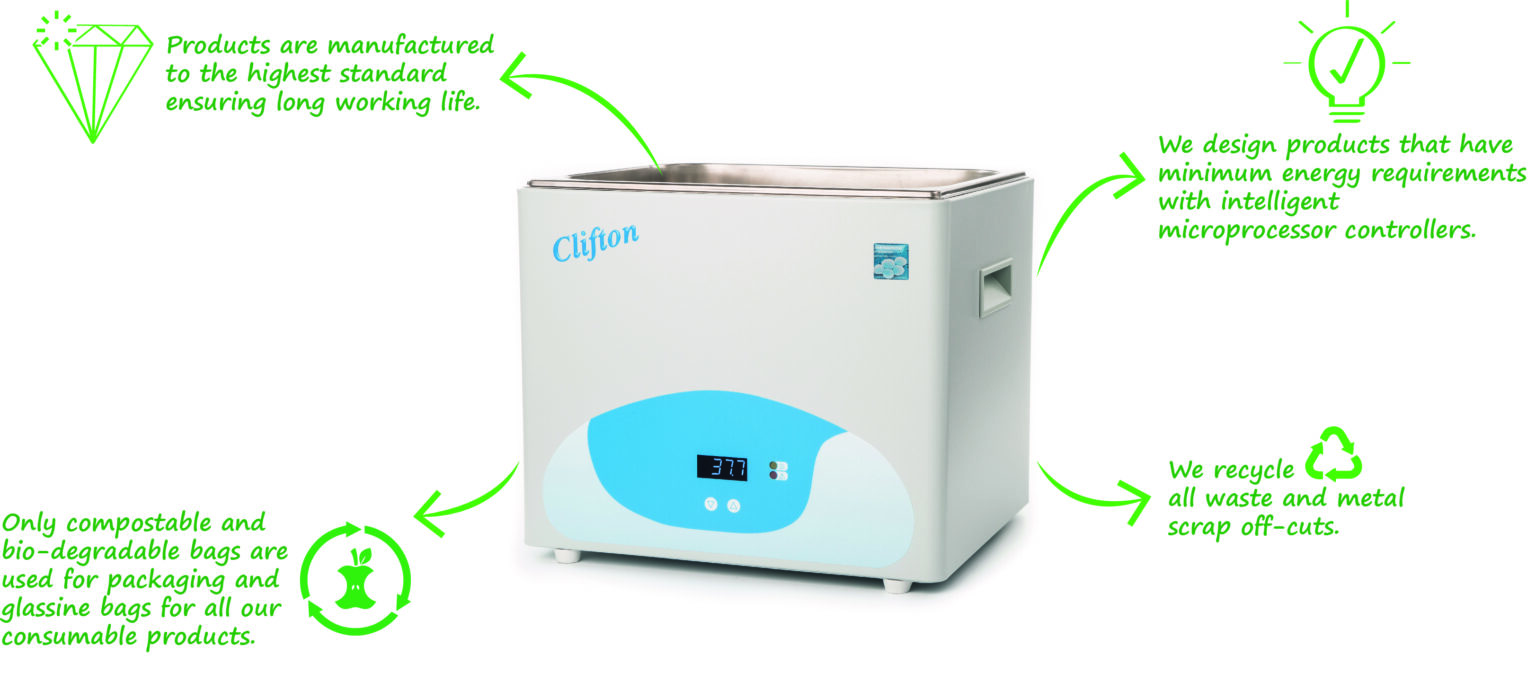

- Low energy products. We design products that have minimum energy requirements with intelligent microprocessor controllers.

- We supply Bath Armor beads for use in our unstirred baths. These are used to replace water. They offer good thermal heat distribution and are eco friendly. They reduce water consumption and are energy efficient

- Products are manufactured to the highest standard ensuring long working life.

- Our parts and components are sourced as close to our manufacturing site and within the UK as much as possible. So no air miles incurred.

Manufacturing Plant, Machinery and Factory Premises

- Lean manufacturing – including regular waste reduction meetings in the factory amongst staff.

- Low factory running costs – we have a streamlined manufacturing process to ensure low energy consumption.

- Main production machinery is electronic not hydraulic, so no oil waste.

- Degreasing plant is non solvent, good for the environment.

- Heat retention curtains in the factory to ensure hot air is contained in the building.

- LED lighting throughout the building and security lamps are low energy sodium lamps.

- Heating system throughout the building is computerised for most efficient use of energy.

- Hot water for our catering facility uses an intelligent water management programme reduces energy costs.

Packaging

- Only compostable and bio-degradable bags are used for packaging.

- Our bubble wrap is bio-degradable and we use paper bags and glassine bags for all our consumable products. Brown paper kraft tape is used to wrap and secure our packages.

- We recycle our cardboard boxes for packing materials, these are shredded to form packing material.

- Local companies deliver their unwanted cardboard boxes to us to shred and use as our own packing material.

- We recycle all waste and metal scrap off-cuts.

- We have recycling bins on site for cardboard, metal, glass and plastic.

- Any safe off-cuts from the manufacturing process are delivered to our local Scrap Store (registered charity) where educational establishments and the local community can use these for crafts and projects.

- Old un-repairable returned products are broken down to component level which are then recycled.

- Factory documentation is protected in bio-degradable sleeves as opposed to plastic wallets. All office paper supplies are recycled.

Company Garden

We have a sustainable and environmentally friendly garden at the rear of our manufacturing building. The garden is home to bee hives and a large fish pond. We grow our own fruit and vegetables and use water collected in butts to water the plants.